Hello folks!

My name is Grant and I have been slowly and methodically developing my own flashlight product over the past few years with my free time. I originally started this project as an engineering hobby aside from my day job as an engineer to test my manufacturing/product design background with a real world product development challenge.

I have always been at least a bit intrigued by flashlights, and a few years ago I purchased a D4V2 flashlight and was absolutely blown away with its capability and range of emitter options (this is coming from a guy who had only ever handled hardware store and cheap Amazon lights). The search of high-quality lights while combing through low-CRI and claimed “1 million lumen + tactical” lights led me to this forum, and I appreciate such a large community like this existing.

To bring clarity to my intentions behind this project, my goal is to create a flashlight that serves as a reliable and repairable tool, not a hotrod, while having well-regarded emitter options available, as well as good quality-of-life features, like ingress protection and USB-C charging. This product will serve as an initial product to kick off my startup business, with the intention of designing thoughtful, useful, (and again repairable) lighting products for many different tasks and trades.

Some basic specifications:

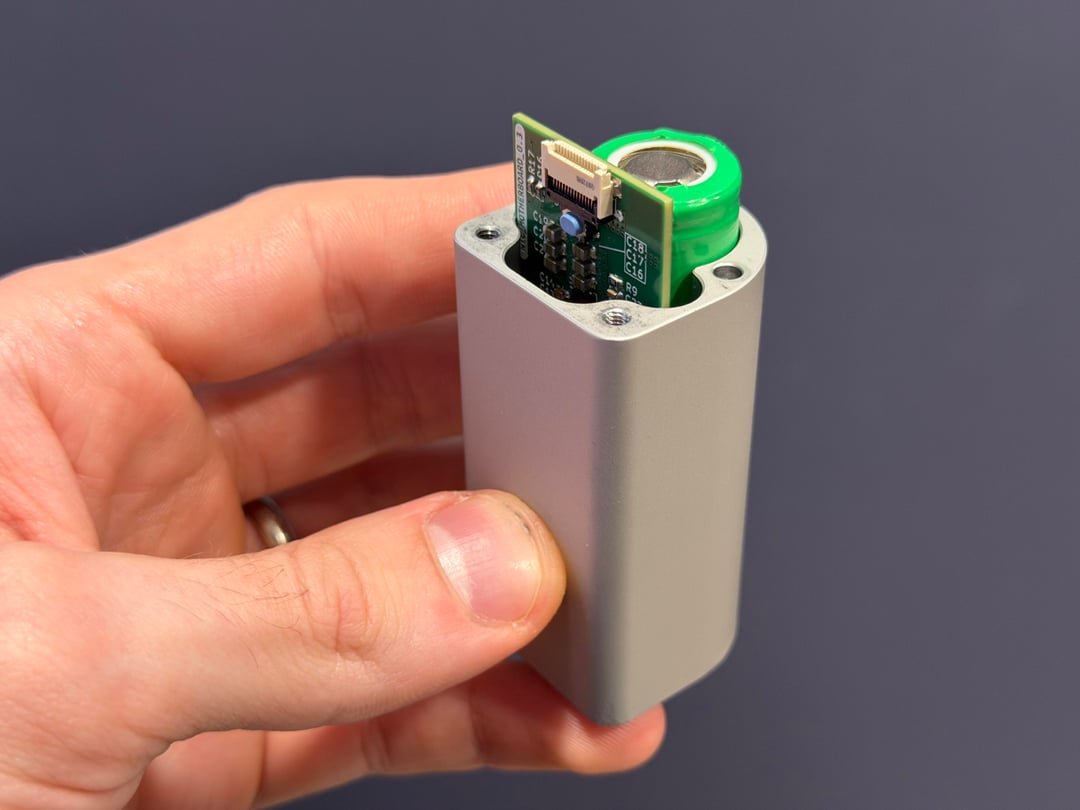

- Body: CNC milled 6061 aluminum (not lathe-turned eh?)

- Clear anodizing looks sick, but will do other colors as well.

- Construction architecture:

- “Sandwich” architecture, with grip, heatsink, and optic cap sealed with flat gaskets and only 2 long screws. This should make maintenance, tinkering, and modding very easy.

- Recessed brass button

- Battery: Basic flat-top 18650

- Emitter: CREE XHP 50.3 HI

- Using this LED because it is a good balance of tint, efficiency, and CRI. Will have other options available, this is just the LED selected before “design-freeze” to make sure things are working.

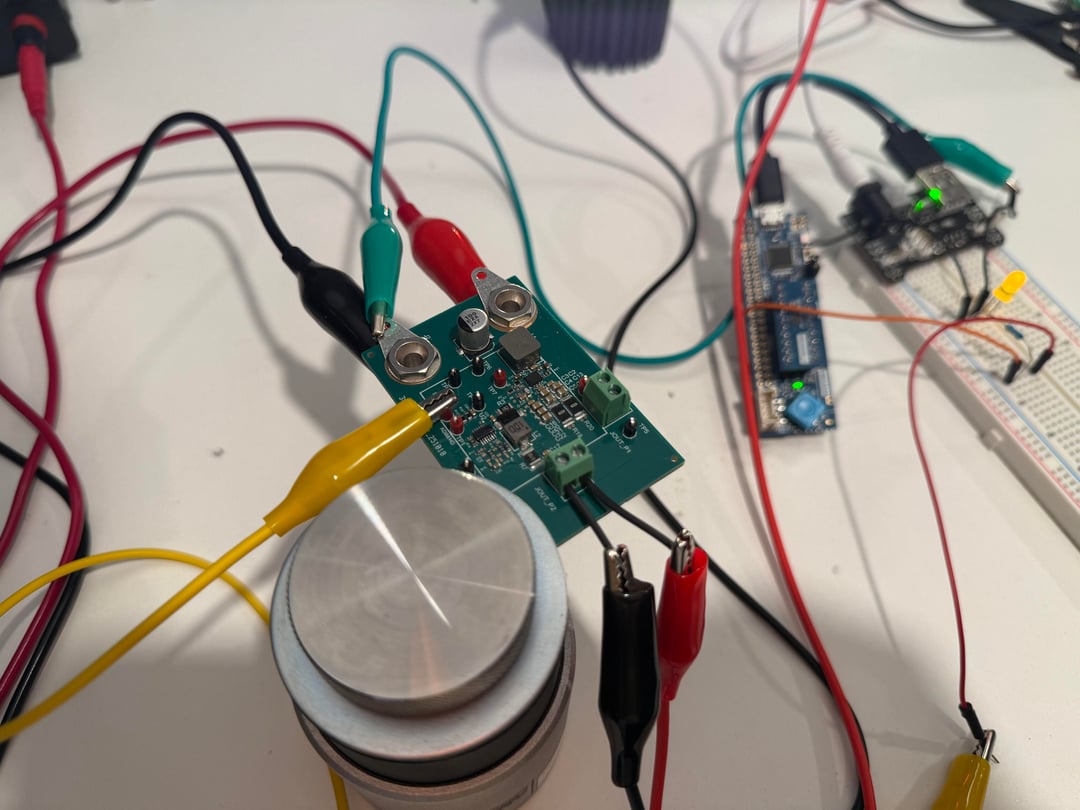

- LED Driver: Buck/Boost architecture (currently targeted for 12V LEDs)

- Strong effort to consider long-term sleep/storage to prevent parasitic drain of battery cell.

- Boost 3.7V to 12V and drive LED with constant current output.

- Temperature derating of LED to ensure it does not burn out (or burn your hand!)

- I am not electrical engineer, so I did hire a contract EE to assist me with both the LED driver optimization, as well as writing firmware to make it work.

- Firmware: Anduril 2 “like” firmware on STM32 chip

- With USB-C charging and NeoPixels implemented, I figured it would be best to write firmware from scratch rather than reverse engineer Anduril 2 onto a 32-bit chip.

- Hopefully this firmware is acceptable. Trying to keep things simple, but take advantage of 32-bit architecture and NeoPixels.

- Optic: 26.5mm Carclo lens. Very common.

- Double AR-coated glass lens to protect the optic

- Pocket clip:

- None yet… have screws to allow addition in the future…

- Should this part be a pacing item for launch? Or add later?

- USB-C charging

- No protective rubber plug or flap on charging port, but IPX8 rating of connector should protect from water and dust ingress (think of the charging port on your phone).

- Perhaps an optional dust cover could be included? Not sure…

- No protective rubber plug or flap on charging port, but IPX8 rating of connector should protect from water and dust ingress (think of the charging port on your phone).

- 4x NeoPixel LEDs

- Battery check indication

- Red light mode?

I aspire not only to create the best product I can, but to also set an example for starting a manufacturing business in today’s competitive and saturated marketplace.

My high-level goal/roadmap is a follows:

- Launch initial flashlight product. Assemble flashlights in-house using outside CNC & PCB suppliers

- Move to a commercial manufacturing space, purchase tooling, make CNC’d parts in house and assemble.

- Purchase equipment necessary to test every product against recognized MIL and ASME standards. Provide tracible test data to customers.

- Create a lean manufacturing line complete with CNC’d part tooling, PCB pick and place equipment, anodizing, etc.

- Create a diverse product portfolio covering many different trades, jobs, and outdoor adventures

- Become a recognized leader in the consumer lighting and lean manufacturing space

Our connected world makes it easier than ever before to reach enthusiasts like you to gather feedback on such a product existing, and what YOU would want to see in a new flashlight product.

I am also looking for your feedback in general on what you think of a company like this existing. Do we need ANOTHER flashlight company? How would I need to set myself apart to be competitive?

At the time of writing this post, the PCB and its firmware are going through a revision to go from a development board to its final form factor, and I am about to perform a pressure decay test on the assembly to ensure correct selection of gasket material and durometer (hardness).

If you are interested in supporting this project, feel free to buy me a coffee (donate to my startup company)! Funding tooling and product validation equipment before launch is the top priority right now.

I am aiming to launch a YouTube channel VERY soon to provide video updates on the development of the project and my journey so far to get to this point. I still have yet to decide if a soft launch like a Kickstarter campaign would be appropriate for this product, or how I should go about that. I will provide an update on what I decide.

I won’t plug myself too much at this time without having a product to sell you yet. Stay tuned for more! I am very excited to share my journey with you all! Thanks!

(DISCLAIMER): If you graciously elect to support this project through a donation, realize that you are donating to my startup company, not to myself as an individual. Your support is sincerely appreciated!

by Street-Brief5479

1 Comment

Damn that was a lot of reading. It definitely needs a pocket clip at release. My personal preference is no onboard charging but I know I’m in the minority here so at least make a cover available, or hide the port to make it look good. Good luck!