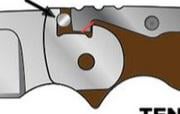

If I ground/filed off the corner of the locking bit on this lockback mechanism (where the red line is), would it be a functional slip joint or would the spring be too weak to hold it open? (I’m trying to find a way to make a Buck 112 EDC legal in the UK.)

by Oo_I_oO

![[NLD] Wurkkos FC11C](https://www.edctips.com/wp-content/uploads/2024/07/3n2k4g32hz9d1-150x150.jpg)

4 Comments

Sorry about the awful quality of the image.

I am not an expert

I think it would work to resist closing like a slipjoint, but I fear the blade would not lock open nicely, but be kinda wiggley instead. There does not seem to be any contact between the bottom surface of the lockbar, and the bottom of the little recess that it goes into. That makes sense, because you’d want to leave a little space there to trap debris.

you’d have only a thin line of contact between the bar and the blade. there’s only so much friction-force a spring can apply to such a tiny area.

you could replace the lockbar with a fitted spring, but that sounds harder. springs are actually pretty easy to make, but the fitting is tough, it’s got to be exactly the right size and the flats have to be parallel and true.

You could just the lock off entirely and get the blade to friction fit tightly between the scales. this isn’t the best solution, but I think that this will be tricky no matter how you approach it

I’m no expert but I believe if it were me I would file down the corresponding part on the blade leaving just a slight lip