We’ve been getting a **shit ton** of misinformation posted on our hardness results posts. So I had [u/Skylark427](u/Skylark427) make a more detailed write up on the hardness/toughness debate that a lot of you seem to misunderstand dramatically. It is not as simple as looking at the charpy ft/lbs compared to hardness value, and drawing a conclusion that harder=less tough. Charpy testing in itself is a very flawed test. The company I work for is not shy in admitting this openly. That said, here is a more detailed write up from Skylark, he knows more than most of you(if not all) because he studied these steels in a professional environment. I hope this clears up a lot of the questions and comments I see.

This is going to be relatively long, and I'm going to need to bring up steels that are similar in design to Magnacut (monocarbide volume only in the heat treated microstructure, assuming a lower austenitizing temperatures, lower tempering temperatures, and cryo heat treatment, from this point referred to as an optimal heat treatment for knives to save space) as a lot of the actual videos and studies done the apex with higher hardness were done with 15V.

Larrin isn't wrong with anything he's saying in that video. I'll start this with that. However, he is typically referring to knife makers themselves, and somewhat to knife companies. One important thing to remember is Larrin, above all, values balance. There's nothing inherently wrong with that. But it's important to remember the types of knives most of us here are using as our EDC knives: smaller folding knives (5 inches and under blade length). If we compare, just for pure cutting, Magnacut at 61Rc vs 64Rc on the type of cutting I do daily, cutting 3 wall corrugated board bolted to shipping pallets that contains metal parts, the assuming the same geometry etc, the 64Rc one would resist deformation of the apex and overall wear for much longer than the 61Rc version. The toughness (which is a lateral toughness test, ISO 148-1 sub size charpy impact specimens, which doesn't fully correlate to the ability of the apex to resist deformation) measurement are for impacts going opposite of the way you use the blade, so overall unless you're prying, or using the edge as a screwdriver, you're unlikely to generate the forces required to cause failure of the edge in that manner in smaller knives.

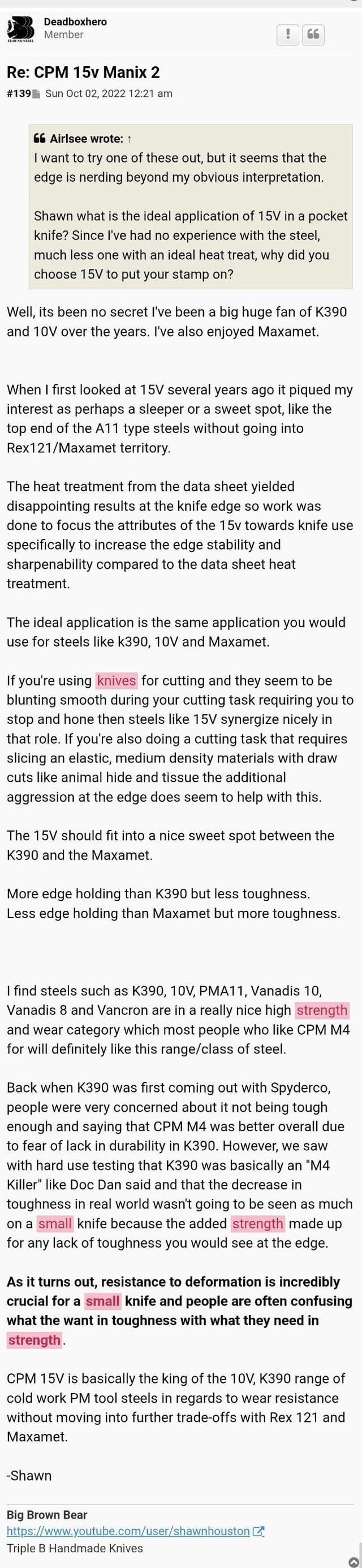

Let's look at what Shawn says about strength in small knives, as strength is often misunderstood with toughness when people have deformation of their edge

He goes on to show us numerous videos over the years of 15V at high hardness (strength) on small knives completely resisting deformation and any damage doing things most of us would never do. Here's a 15V custom he made at basically factory geometry at 67Rc he proceeded to chop through a 16d framing nail on his anvil with a splitting maul, no damage to the edge:

https://m.youtube.com/watch?v=bliUWSXm09o

Here he carves and torques the factory edge of a 15V Paramilitary 3 at 65.4Rc on African Blackwood, an incredibly dense wood. Worse than torqueing straight against a knot on most hardwoods:

https://m.youtube.com/watch?v=JDeNOaKdpTw

Here's an article that shows just how the high strength of the matrix on a 2022 15V Manix G10 (65-66Rc) resists flexing of the sub micron apex just on sharpening, this translates to a macro scale as well:

https://scienceofsharp.com/2024/01/18/carbides-in-15v/

I've hacked into live silver maple wood with 15V, S110V, 4V, and MagnaMax (prototype batch 2), all at over 65Rc besides the S110V (63.7Rc), and batoned with the 15V Mule (66.4Rc) and MagnaMax Mule (65.1Rc) through 2-4 inch thick branches. I've also carved into aluminum barstock, pennys, and deburred mild steel with both. Because the blades are not overly large, the amount of torque required to cause failure of the apex falls more on strength than toughness, otherwise the 4 ft-lbs 15V is rated at by Larrin was exceeded in each video. This is why strength is very important in small knives. Of course, how this strength is reached is equally important, an optimal heat treatment at 64Rc vs a non optimal heat treatment at 64Rc will not have the same stability at the apex.

Part 2:

This is where monocarbide volume only steels shine, they're typically capable of having similar wear resistance in the real world to the higher wear resistant high speed steels (as monocarbides are the hardest, smallest types of carbides besides some very tiny secondary carbides like eta and epsilon transition carbides, at around 8-10% carbide volume secondary carbides tend to no longer be small, they'll tend to clump together in large clusters due to the rapid nature of precipitation hardening and how they'll segregate to grain boundaries and dissolve into themselves as larger carbides or become soluble in other primary carbides).

Another way if looking at this (again, mainly small knives we're talking about here), is as shown in that Science of Sharp article with SEM, the steel matrix being harder supports the very hard and brittle carbides themselves more. Say you have M390 at 59Rc, and another M390 blade at 63Rc, both the same blade, same optimal heat treatment. Just because the matrix is at 59Rc, doesn't mean the chromium/vanadium carbides aren't still at 81Rc, and still just as large (larger actually because as hardness increases, more carbide is dissolved into solution of the matrix making them smaller), so you will have a 59Rc blade more likely to have an edge roll, that will hit a carbide then turn to a crack. This is another reason why strength is very important on smaller knives. Again, assuming an optimal heat treatment. I studied these alloys for my line of work.

That's all I've got time for currently.

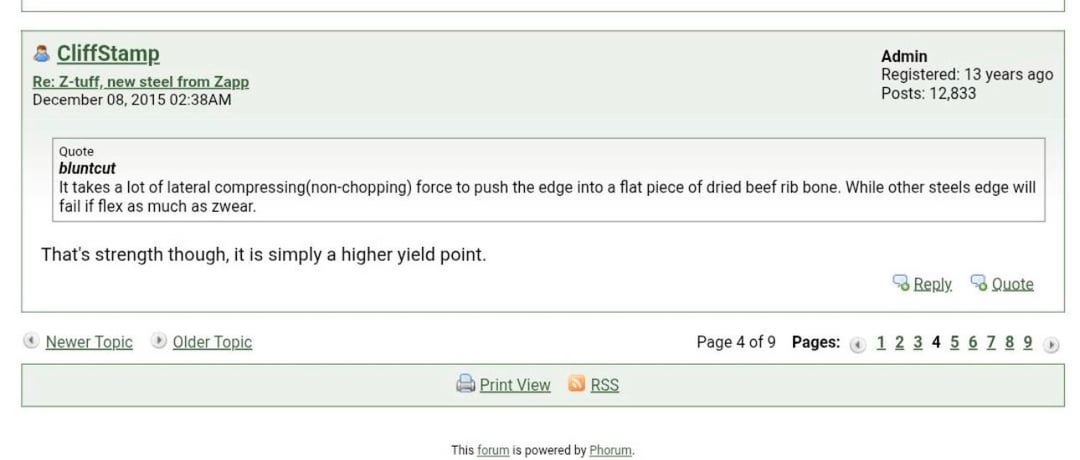

Adding another screenshot from the late Cliff Stamp to show just how often strength and toughness are confused for deformation on edges of knives

The yield point of the strength and how well it increases stability of the edge itself is typically highest on steels that only have monocarbidess in the heat treated microstructure(like Magnacut, 4V, 10V, K390, Vanadis 8, 15V, and now MagnaMax).

One thing all the scientists agree on though, from Cliff Stamp to Roman Landes to Larrin Thomas is that high hardness/strength is needed for high stability of the apex.

by 679696