Sample 1 averaged 58.6 HRC across 8 punches using Rockwell Hardness.

Sample 2 averaged 58.2 HRC across 8 punches using Rockwell Hardness.

Sample 1 & 2 were cross sectioned using an Allied Techcut 5 at the tip, and near the further 1/3rd of the blade using sufficient cutting fluid to prevent burning.

Sample 1 was notched to ensure traceability.

Both pieces from Sample 1&2 were put in a clip and mounted in Buehler Epomet powder. Buehler Simplimet 3000 using 4,200 PSI to create the mount. Mount containing sample 1 and 2 was then scribed with “OT D2 Test”. Mount was then machine polished using 250rpm at 5 pounds of force per sample(15 total pounds) on a Buehler Ecomet 4, with 60, 180, 320, 600, 6 Micron, and finally 1 Micron polishing pads. Mount was then sprayed with methanol and dried with a Milwaukee heat gun.

A 500 gram Knoop verification block was then tested on a Clark CLC-10ARS and found to be well within +/-10 points of the given value. A microhardness traverse was then ran starting from the edge of the blade and ending in the core of the blade, with each consecutive punch being 0.003” deeper than the previous punch.

Sample 1, piece taken towards the tip:

Core averaged 59.2 HRC.

Overheating reached a depth of 0.024”

Note: the first punch was too wide(soft) for a proper measurement to be made.

Sample 1, piece taken towards the center:

Core averaged 59.0 HRC

Overheatinf reached a depth of 0.018”

Note: the first punch was too wide(soft) for a proper measurement to be made.

Sample 2, piece taken towards the tip:

Core averaged 58.0

Overheating reached a depth of 0.033”

Note: the first punch was too wide(soft) for a proper measurement to be made.

Sample 2, piece taken towards the center:

Core averaged 57.6 HRC

Overheating reached a depth of 0.015”

Note: the first punch was too wide(soft) for a proper measurement to be made.

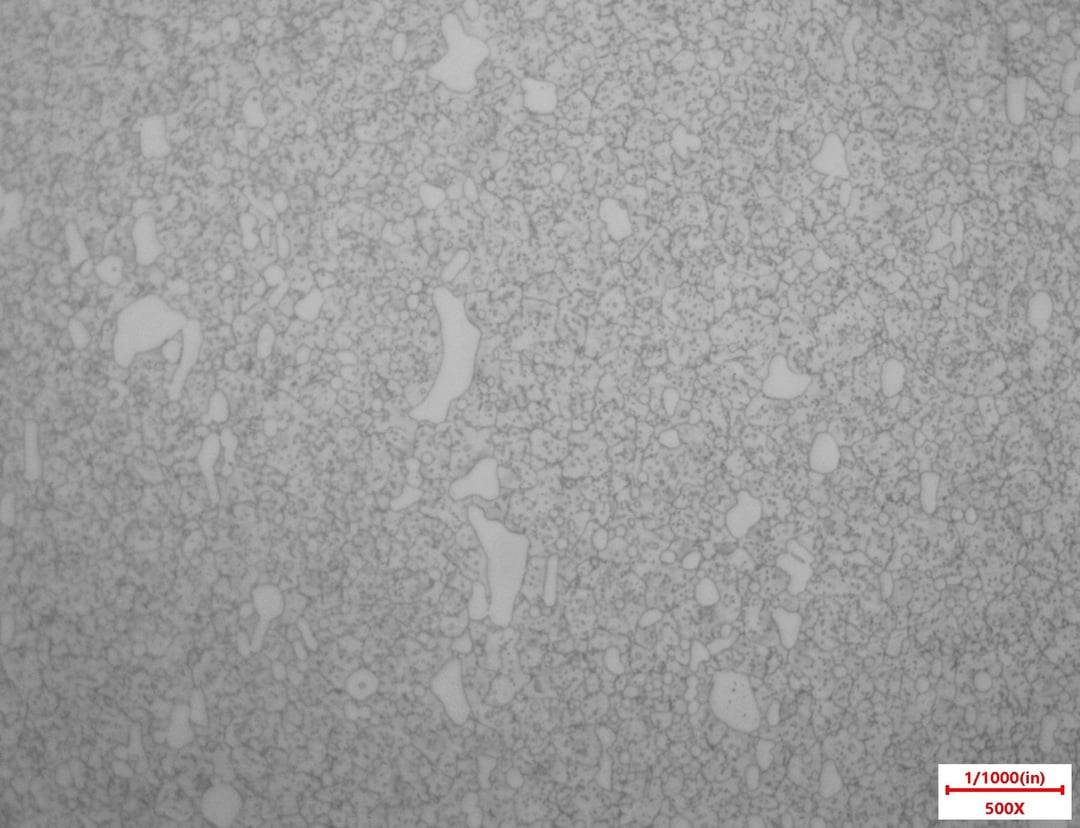

Samples were then evaluated in the “as polished” condition using a Zeiss Axiovert 40 MAT between 25x and 500x. No signs of overheating were found in this condition.

Samples were then etched with a 2% Nital solution for a few seconds, sprayed with methanol and dried with Milwaukee heat gun.

Etching was repeated until a proper grain structure was visible.

Samples were then evaluated using a Zeiss Axiovert 40 MAT between 25x and 500x.

No visual signs of overheating were observed on any of the 4 pieces. A carbide rich, Martensitic microstructure was observed throughout the pieces.

TLDR; All 4 pieces showed signs of overheating when evaluated using ASTM E384 microhardness testing. The depths of which varied significantly between pieces.

by 679696

1 Comment

Paging u/Skylark427