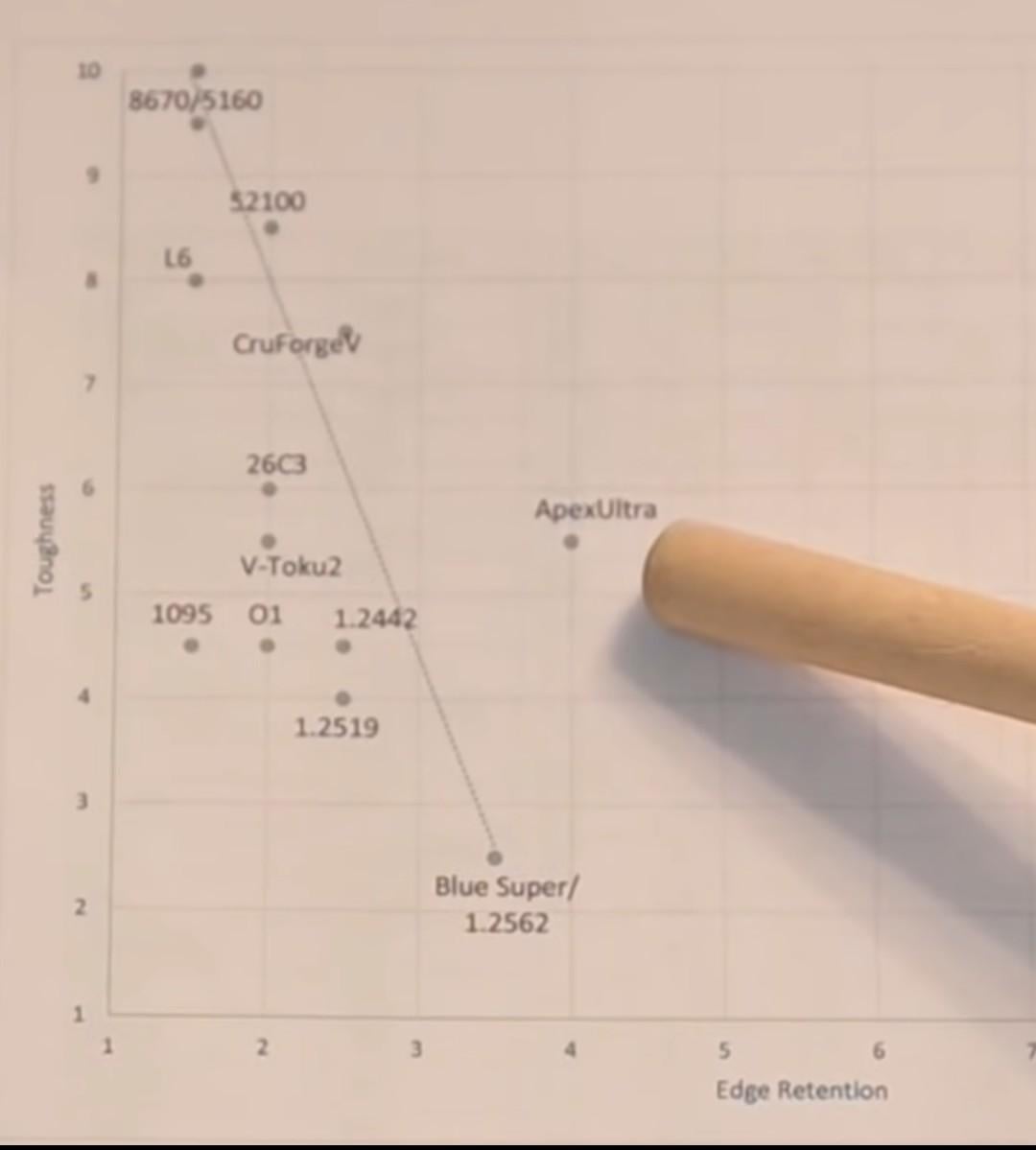

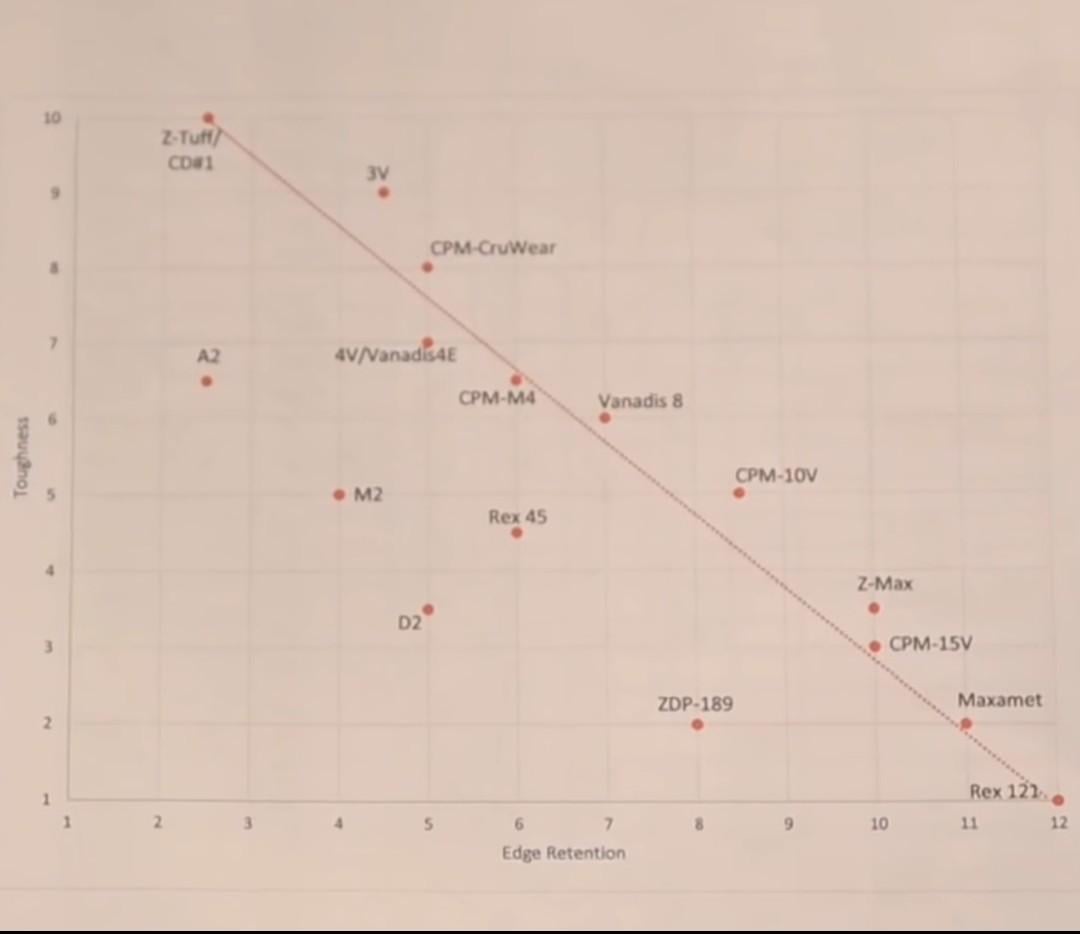

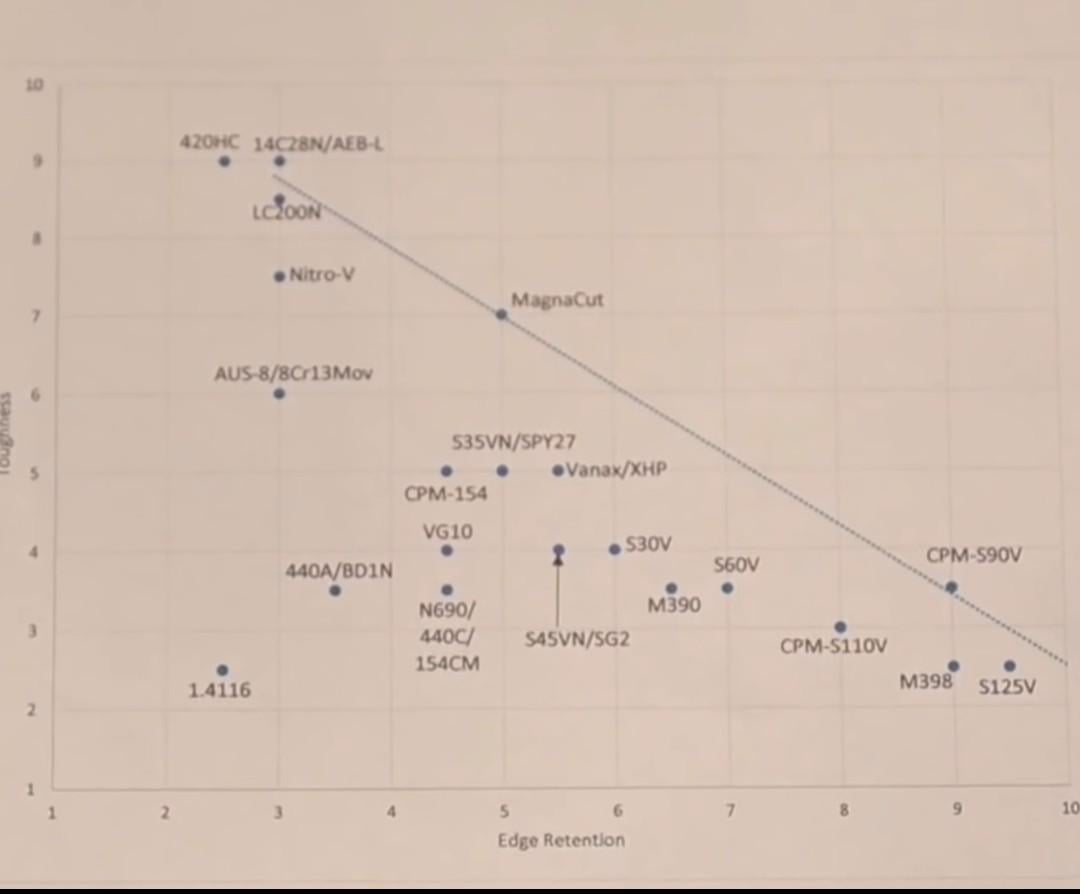

I just watched the "KnifeSteelNerds" video about knife steels. He shows 3 graphs that plot the edge retention and toughness of various steels. My question is this: since the steels are categorized in 3 different categories (carbon steel, high allow tool steel, and stainless steel), are the toughness and edge retention values empirical or relative?

I ask this question because I was under the impression that carbon steels were tough. But if I read these charts literally, they show that a lot of stainless steels have higher toughness than 1095 (for example). Is that the case?

1095 is shown to have a toughness of around 4.5. AEB-L is shown to have a toughness of 9. Is AEB-L really twice as tough as 1095?

I understand that these values likely assume proper heat treatment and manufacturing.

by Spyrothedragon9972

5 Comments

Yes AEB-L is tougher than 1095. yes the scale is saying its double the toughness. thats what that means.

The article that accompanies the video has a lot more information, including a different version of these charts that shows toughness measured in foot pounds vs Rockwell hardness: https://knifesteelnerds.com/2021/10/19/knife-steels-rated-by-a-metallurgist-toughness-edge-retention-and-corrosion-resistance/

You can see on these charts that AEB-L can have a huge range of toughness depending on how it’s hardened, from low hardness (60) and high toughness (38) to high hardness (64) low toughness (12). In contrast, 1095 can vary between low hardness (57) high toughness (10) to high hardness (61.75) low toughness (5).

So yes, 1095 is nowhere near as high performing as AEB-L. In general, some of the best performing steels are stainless, and simple carbon steels can’t touch them. Some carbon steels perform better than others, though, which is why you see good makers using 52100 instead of 1095.

I majored in mechanical engineering, I love the study of steel.

What metric did he use for toughness? What metric for hardness?

These graphs are all over the place. Why is O1 and 52100 on the carbon steel graph? Those are tool steels.

Rex 121 (on the tool steels graph) has 1 toughness but 12 edge retention? That makes no sense.

From a material science point of view, these graphs are jacked. Toughness is probably the best property you could reference to compare edge retention, and these graphs show an inverse relationship. The fact that there’s no actual units or values given is frustrating.

Plus; 1095, 52100, 5160, and O1 are all really low on the edge retention scale, <=2. Those steels have awesome edge retention when heat treated properly.

This is why we label the chart axis with the units. Toughness is kind of a vague term. Is it the max shear stress of the blade? Or is it the elastic deformation modulus (the max force where the steel will bend back to the original state). Theres a lot of numbers which can be used to quantify toughness.

Even if it is qualitative, I don’t see why the scales would change between the charts when the entire point of the charts is to compare different steels. I would imagine the reason they were separated would be to make the charts easier to read. Each chart has steels which are relatively similarly corrosion resistant with carbon, semi-stainless, and stainless steels.

The only person who can answer whether they can be compared is the person who created them. Unless his website explains his methodology theres no definitive way to know if the different charts are directly comparable.

i presume you are asking why some companies use 1095 for outdoor over AEB-L. from what i understand is that anything over a 4 is considered “tough enough” for a fixed blade. so some companies feel confident in their choice of using a 1095 over AEB-L. AEB-L like all steels during the manufacturing process can warp. from my understanding when a steel like that warps due to its toughness, its nearly unsalvageable if not done right. so in my honest opinon AEB-L smokes 1095 and the only reason why some companies use it because its good enough and cheap to produce.